JagSeis® (US patent number 8,694,260 B1), is a web-based data management software application for our Quality Control consultants and clients to monitor all phases of seismic data acquisition projects:

- Supervision and Acquisition QC (AQC) is primarily involved with seismic data acquisition operations and technical compliance.

- Geodetics QC (GQC) is associated with field positioning of all points, plus line clearing.

- Health, Safety and Environment (HSE) addresses all phases of the seismic field operation from an HSE perspective.

Compliance

JagSeis® was developed based on international industry guidelines and best practices. This software application can securely analyze, evaluate, send, receive and archive critical field operations data via the Internet.

Provides a comprehensive software application system for our consultants and clients to track and monitor the progress of seismic projects, anytime from anywhere, for more timely and effective management decisions.

Benefits

- Reliable, validated and integrated seismic project information easily interfaceable with Client’s corporate systems

- Management and control of the entire seismic project from one location:

- Compliance with contract specifications

- 24-hour data viewing

- Contractors’ performance

- Promote client’s HSE-MS standards

- Liaise, support and supervise remote personnel

- Track QCs’ performance

- Proof of performed activities

- Effective quality control results from:

- Integrated information readily available for timely decisions

- Systematic approach with established procedures and guidelines

- Reduced errors by replacing manual data input with digital capture

- Built-in QC tools

- Semi-automatically generated reports

- Compensating for different professional backgrounds

Features

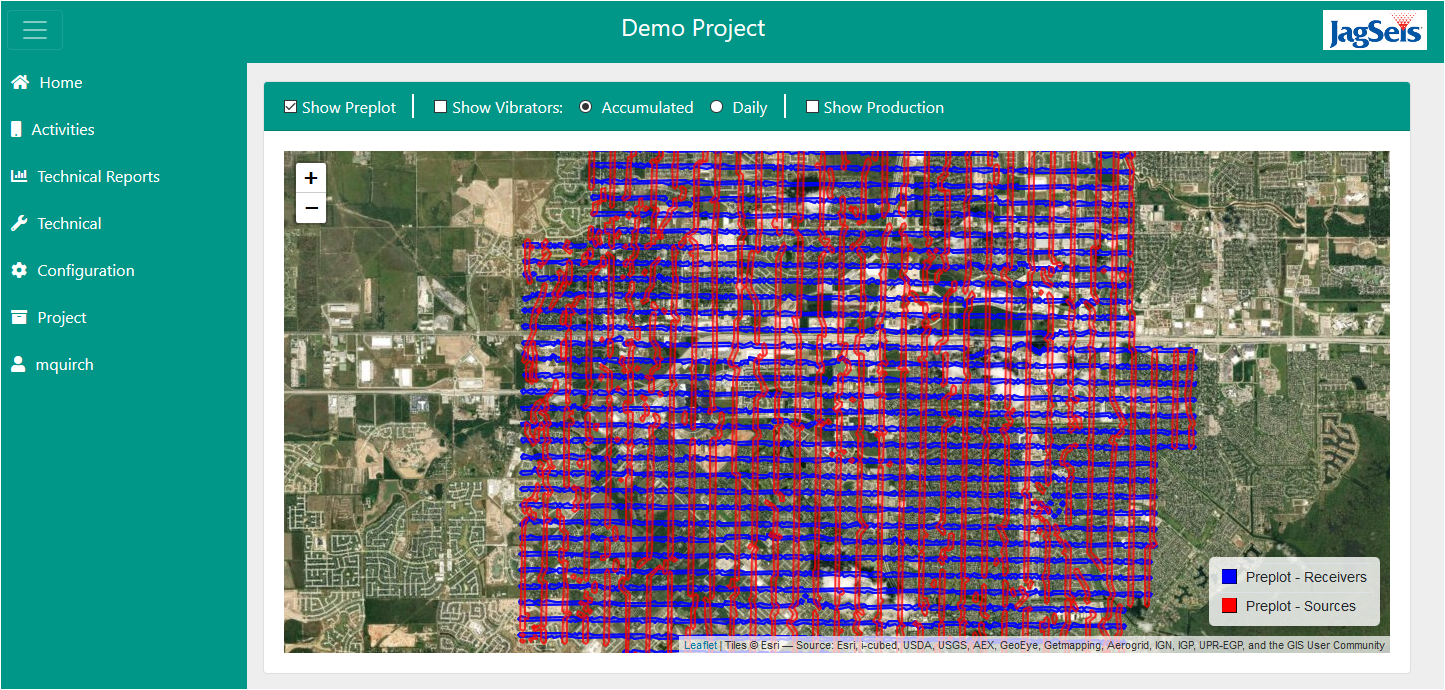

- Displays pre-plots and generates post-plot maps and production statistics for surveying and acquisition (planned vs. actual production)

- Displays data captured with hand-held GPS units (date and time stamp; line and station number, as well as location by X-Y coordinates, where the QC inspection was performed)

- Quality Control for surveying & positioning:

- Tracks and displays offsets, skips and recovered source points

- Tracks and identifies out of specification source and receiver locations

- Helps the field QC to identify survey network monuments and horizontal and vertical accuracy limits

- Helps the field QC to identify positioning errors and equipment errors by using the Query Analyzer (PDOP, # of Satellites, etc.)

- Quality Control for Acquisition:

- Instrument Analysis and Audits based on contractual and manufacturers’ specifications

- Equipment and Explosives Inventory management

- Interface with cable and nodes recording system

- Drilling Performance (shot hole depth)

- Reads the ADSTA files (Trace and Shot Domain Attributes). Identifies defective channels

- Vibrator performance (maps of distortion, phase, force, etc)

- Up-hole time monitoring

- Generates fold plots. Allows the QC to follow acquisition progress to make sure that Nominal Fold will be obtained

- Generates Rose Diagrams: Fold and Offset (Distance and Azimuth) distribution

- Tracks helicopter statistics

- Populates and generates pre-configured daily and weekly report templates and assists in compilation of graphs, tables and displays for monthly and final reports

- Quality Control for HSE:

- Dynamic and unique “HSE EYE” for effective visual tracking of the HSE Management System

- Online review and daily graphics of HSE-MS performance for seismic projects

- Notifications/Alerts for agreed upon critical elements

- Based on industry standards and best practices

- Compliance with governmental regulations

- Inspections and Audits for prevention of incidents

- Corrective Actions and Incident management

- Tracking of Key Performance Indicators

- Location, date/time and inspection data of camps, helipads and other physical sites can easily be gathered with hand-held GPS/digital camera units and effectively displayed on maps